![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/c/7/csm_wiehag-crossrail-canary-wharf-09_c2e361890b.jpg)

175 years of

Timber Construction Know-how

Milestones in timber engineering

Our history

With our history of 175 years, we have significantly influenced the development of timber engineering. Today we are still pioneers in the timber construction industry, setting the tone in terms of engineering expertise, pioneering buildings and sustainability.

Timber engineering experience for generations

Since 1849, the Wiesner family has been continuously involved in timber construction, now in the 5th generation.

Master carpenter, Josef Wiesner, was the founder. He registered as a member of the carpenters’ guild in May 1849 in Altheim, Upper Austria. A globally active timber construction company emerges from a workshop and an open-air joinery.

![[Translate to Englisch:] Gründer Josef Wiesner [Translate to Englisch:] Gründer Josef Wiesner](/fileadmin/_processed_/7/0/csm_wiehag-josef-wiesner_127896f3c6.jpg)

Early pioneering buildings that point to the future

Austria Pavilion at the New York World's Fair – a pioneering achievement in prefabrication (1964)

Austrian star architect Gustav Peichl wins the competition to construct this exhibition building with his design. "The fact that timber has been a main material of domestic architecture for centuries and is today a valuable export commodity for Austria" proved to be an advantage even then. In addition to that came the fact that timber as a building material is ideal for prefabrication, thanks to WIEHAG engineering. The individual parts of the pavilion, planned according to the modular principle, were prefabricated at WIEHAG in Altheim and assembled on site in New York.

![[Translate to Englisch:] Austria Pavillon auf der New Yorker Weltausstellung [Translate to Englisch:] Austria Pavillon auf der New Yorker Weltausstellung](/fileadmin/_processed_/b/b/csm_wiehag-austria-pavillion-1964_dbbb845d53.jpg)

The Klagenfurt Exhibition Hall – the largest glued laminated timber hall in Europe

At the time, construction of the arched-girder hall with a span of almost 100 m represented an incredible technical and organisational achievement. Never before had such a large timber structure been designed for such a high snow load, namely 200 kg/m².

The individual glued laminated timber beams were manufactured at the factory in a length of 55.5 m, dismantled into three parts for transport by rail, and then reunited on the building site using a patented assembly joint.

The hall is not only unreservedly admired by the general public; it is also described by timber construction experts, both national and international, as a pioneering achievement in glued laminated timber construction.

![[Translate to Englisch:] Die Klagenfurter Messehalle [Translate to Englisch:] Die Klagenfurter Messehalle](/fileadmin/_processed_/f/6/csm_wiehag-messehalle-klagenfurt-1966_eece0d18c3.jpg)

Eco Power Act

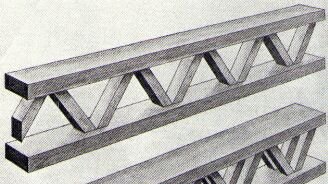

Not only wide-stretched, but also strong as an ox!

How many army tanks can WIEHAG hang on a high-performance timber beam stretched over a distance of 30m? With this question WIEHAG invited the media and the expert public to the WIEHAG factory on 30.10.1996 for a true wooden construction spectacle.

One after the other, 5 army tanks from the Ried im Innkreis barracks are hung on a high-performance timber beam developed by WIEHAG, which serves as an alternating beam between two hall aisles of the company's own production. The timber truss girder carries around 80 tonnes at each of the three quarter points. WIEHAG once again proves its engineering competence and pioneering spirit.

![[Translate to Englisch:] WIEHAG hangs tanks on timber beam WIEHAG Panzer auf Leimbinder](/fileadmin/_processed_/f/3/csm_wiehag-panzer-leimbinder_1a042cfb37.png)

New standards in the industrial production of GLT project components

WIEHAG bets on the future of timber construction and in 1999 opens the most modern and largest production plant for project components with a multitude of innovations. For the first time a control technology is programmed and used, where production orders can be accepted online in combination with work preparation and construction. The world's first CNC press for glued laminated timber components up to 50 metres is successfully developed and built in close cooperation with the machine manufacturer. Similarly, a CNC machining centre for the extra-long beams.

![[Translate to Englisch:] WIEHAG Werk [Translate to Englisch:] WIEHAG Werk](/fileadmin/_processed_/4/1/csm_Werk_Luftbild_d85358337a.jpg)

Timber construction prevails

Large-scale timber buildings

WIEHAG goes international

With the new high-capacity facility, WIEHAG is expanding into new markets and enhancing its competitiveness with other building materials. The company successfully secures its first projects in England and prevails in prestigious large-scale constructions against competing materials. WIEHAG thus demonstrates that timber construction can be both technically superior and economically viable.

International architecture

WIEHAG next level engineering

Internationally renowned star architects and Pritzker Prize winners are increasingly turning to WIEHAG's engineering expertise for their projects. Among them are Norman Foster, Rogers Stirk Harbour & Partners, Coop Himmelblau, Kengo Kuma, and Toyo Ito. Through close collaboration, award-winning architectural structures are created, showcasing the brilliant design potential of timber as a material.

Mass timber components for high-rise construction

Reaching for the skies with WIEHAG

Around the world, the first wooden skyscrapers are being planned and constructed in urban areas. WIEHAG is at the forefront as a pioneering company. Their comprehensive technical expertise, production know-how, and capability to manage large-scale projects on international markets are in high demand.

With projects like the K5 in Brisbane, the faculty building for Nanyang University in Singapore, and the Ascent Tower in Milwaukee, WIEHAG is responsible for the tallest timber building in Australia, the largest timber construction in Asia, and the tallest timber high-rise in the USA. These achievements underscore WIEHAG's leading position in this growing market segment.

WIEHAG PUSHES THE BOUNDARIES IN TIMBER CONSTRUCTION

HIGH TECH LOW CARBON SOLUTIONS

By the end of 2022, the new WIEHAG facility will be in full operation. The state-of-the-art timber framing center for large-volume, laminated composite components will process its initial large orders. Finished wooden components can be delivered worldwide as construction kits, including all necessary fasteners, with unprecedented precision. This significantly reduces assembly times, saves costs, and reduces on-site risks.

The unique expertise and capabilities of WIEHAG are further demonstrated by the completion of the new World of Volvo and the award of the contract for the world's tallest timber-hybrid skyscraper, the Atlassian Tower in Sydney, scheduled for completion by the end of 2026.

![[Translate to Englisch:] World of Volvo Innenansicht [Translate to Englisch:] WIEHAG Holzbau World of Volvo](/fileadmin/_processed_/3/f/csm_Rasmus_Hjortshoj__World_Of_Volvo_WEB-1_767b83e613.jpg)

![[Translate to Englisch:] WIEHAG Holzbau Messehalle Karlsruhe](/fileadmin/_processed_/4/2/csm_wiehag-neue-messe-karlsruhe-4_37ccbc88ba.jpg)

![[Translate to Englisch:] Eissporthalle, Erfurt](/fileadmin/_processed_/8/f/csm_wiehag-erfurt-eissporthalle2_ca8f6fb670.jpg)

![[Translate to Englisch:] WIEHAG Holzbau bei Macallan Destillerie Schottland](/fileadmin/_processed_/8/7/csm_macallan-destillerie_85db3ba43b.jpg)

![[Translate to Englisch:] Paneum Asten](/fileadmin/_processed_/6/5/csm_wiehag-paneum-01_132c7ffe44.jpg)

![[Translate to Englisch:] NTU Singapur, WIEHAG Holzbau NTU Singapur Außennansicht](/fileadmin/_processed_/1/2/csm_wiehag-ntu-singapore-8_40c4882544.jpg)

![[Translate to Englisch:] The Import Building, London](/fileadmin/_processed_/f/0/csm_wiehag-import-building-01_93098f89e3.jpg)

![[Translate to Englisch:] UBM Timber Pioneer Timber Pioneer Brettschichtholz Tragstruktur](/fileadmin/_processed_/6/c/csm_wiehag-timber-pioneer-2_f639576777.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/1/5/csm_wiehag-175-jahr-feier-1_407410e726.jpg)

![[Translate to Englisch:] The World of Volvo [Translate to Englisch:]](/fileadmin/_processed_/e/a/csm_James_Silverman-World-of-Volvo-00551_ad4293d316.jpg)