The Klagenfurt

Exhibition Hall 3

Challenge Accepted

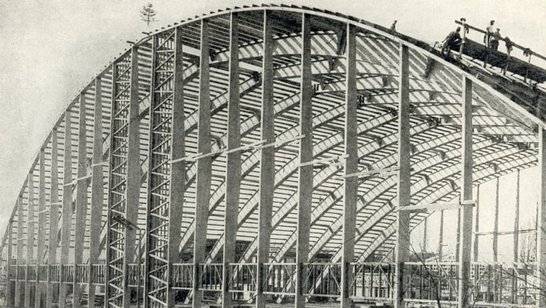

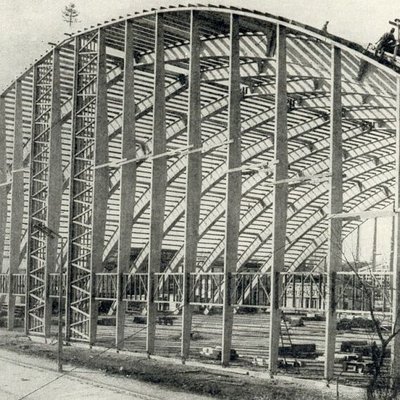

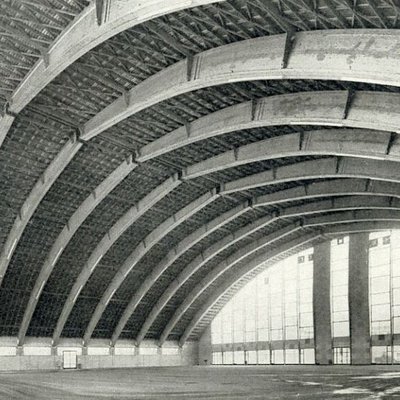

The task of spanning 96 meters with an unusually high snow load of 2.0 kN/m², distributing gable wind loads of 780 kN across the roof surface to the longitudinal walls, and calculating, drawing, producing, and assembling 1,300 m³ of glued laminated timber in a few months posed a challenge of an entirely new dimension for timber construction in 1965.

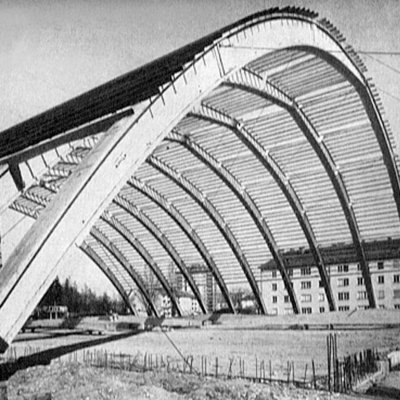

Wooden arch trusses were chosen as the main support structures. The base joints are located 80 cm above the ground, from there the arch trusses rise at an angle of 45 degrees, reaching a peak height of 25.3 m. The load-bearing hall structure consists of 10 trusses spaced at 6.80 m intervals. Corrugated asbestos cement sheets were chosen for the roof covering. Nails are used for connecting the rafters to the trusses, and Geko dowels with screws are used for the rafter joints and for connecting the wind bracing struts to the rafters

Transport and Installation under Challenging Conditions

A semi-arch, initially crafted as a single 55.5-meter piece at the factory, had to be divided into three sections of approximately 18.5 meters each for transportation purposes. These components were then transported to the construction site via thirty railroad cars and reassembled into 55-meter-long beams using assembly joints within an existing hall on-site. Due to the winter weather conditions, an additional cabin was erected and equipped with heating and air conditioning to facilitate the gluing of the assembly joints. Such precautions were necessary to ensure the integrity of the assembly gluing process.

The assembly of the 10 trusses was completed within 10 days. Two mobile 50-ton cranes were employed to simultaneously lift two half-trusses into the abutments and unite them at the ridge joint. This process required two installers to climb onto each half-truss and coordinate the alignment at the ridge joint.

- Client

- Österreichische Holzmesse Klagenfurt

- Architect

- Dipl. Ing. Otto Loider, Wien

- Construction period

- 1965/1966

- BSH volume

- 1.300 m³

- WIEHAG scope of work

- structural analysis, design, production, and assembly of the supporting structure

![[Translate to Englisch:] World of Volvo, Timber Construction by WIEHAG [Translate to Englisch:] WIEHAG Timber Construction in der neuen World of Volvo](/fileadmin/_processed_/1/2/csm_James_Silverman-World-of-Volvo-8504254-205x_295-2_02f4d6a393.jpg)

![[Translate to Englisch:] Logistikzentrum Edeka Marktredwitz [Translate to Englisch:] Edeka Logistikzentrum](/fileadmin/_processed_/e/4/csm_20230531_091635_b0b24cb06b.jpg)

![[Translate to Englisch:] Nanyang Technological University Singapore [Translate to Englisch:] Nanyang Technological University Singapore](/fileadmin/_processed_/7/8/csm_wiehag-ntu-singapore-13_379b8f5c43.jpeg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/d/8/csm_SZMC_Farrow_Rubinstein_Ofer_Architects_Photography_by_Harel_Gilboa_credit-24_9b10786474.jpg)

![[Translate to Englisch:] Ascent Tower, Milwaukee [Translate to Englisch:] Ascent Tower, Milwaukee](/fileadmin/_processed_/1/b/csm_wiehag-ascent-tower-milwaukee-1__13__02dbe783b2.jpg)