Rowing Pavilion

A Fusion

of Structural Engineering and Architecture

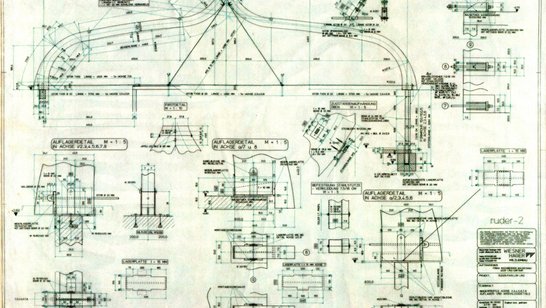

For a building structure measuring 16 m x 16 m in system dimensions, laminated timber 3-hinged trusses with a cross-section of 14 cm x 42 cm were used, spaced 2m apart, each with horizontal tie rod closure of the supports using ISTOR Ø 20 mm. The static system height was 3.95 m at the ridge. The beams were supported unilaterally on anchored steel formwork tube supports 150/150/5 at +2.60 m, while on the opposite side, reinforced concrete walls served as supports.

The roof construction consisted of a copper sheet roof on formwork and cardboard, counter-battens (curved in the narrow curved roof areas), 8cm rigid foam insulation, cardboard, and over the truss spacing of 2 m, a 40 mm F30 load-bearing formwork.

Masterful

Roof Geometry

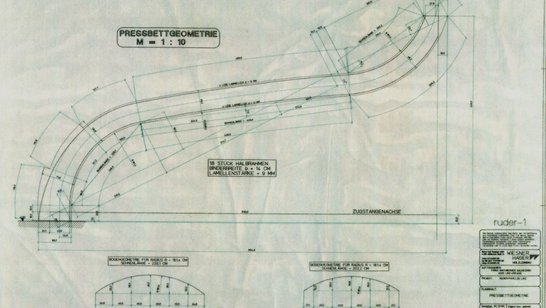

The geometry of the unique roof shape was created with three transitioning arch radii per half beam. Starting concave from the support with a radius of 1.85 meters, then transitioning to a concave radius of 36 meters over a length of approximately 4.50 meters, and ascending to the ridge in a convex form with a radius of 1.85 meters. To achieve such tight bending radii with the 42 cm high beam cross-sections, individual lamellas of only 9 mm thickness had to be manufactured.

The structural analysis also revealed that in the middle section with a 36-meter radius, there were only minor transverse tensile stresses, and in the concave lower small radius section, only negative moments with transverse compression were formed. In the upper small radius section - towards the ridge - although there were positive moments, due to the convex shape, transverse compression was also present.

An architectural enhancement consisted of curved 10/8 cm visible roof ribs on the exterior side of the roof, which were clad in sheet metal and visually indicated the roof construction.

In appreciation of the realized architecture, the structure can still be considered a showcase project of WIEHAG's competence in engineered timber construction today.

- Client

- OÖ. Landesruderverband

- Design

- Architekt Dipl. Ing. Helmut Ortner, Puchenau

- Structural Engineering

- Ziv. Ing. Dipl. Ing. Helmut Schiebel, Linz

- Timber Structural Engineering

- WIEHAG

- Production Planning

- WIEHAG

- Completion

- 1991

![[Translate to Englisch:] World of Volvo, Timber Construction by WIEHAG [Translate to Englisch:] WIEHAG Timber Construction in der neuen World of Volvo](/fileadmin/_processed_/1/2/csm_James_Silverman-World-of-Volvo-8504254-205x_295-2_02f4d6a393.jpg)

![[Translate to Englisch:] Logistikzentrum Edeka Marktredwitz [Translate to Englisch:] Edeka Logistikzentrum](/fileadmin/_processed_/e/4/csm_20230531_091635_b0b24cb06b.jpg)

![[Translate to Englisch:] Nanyang Technological University Singapore [Translate to Englisch:] Nanyang Technological University Singapore](/fileadmin/_processed_/7/8/csm_wiehag-ntu-singapore-13_379b8f5c43.jpeg)

![[Translate to Englisch:] Ascent Tower, Milwaukee [Translate to Englisch:] Ascent Tower, Milwaukee](/fileadmin/_processed_/1/b/csm_wiehag-ascent-tower-milwaukee-1__13__02dbe783b2.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/d/8/csm_SZMC_Farrow_Rubinstein_Ofer_Architects_Photography_by_Harel_Gilboa_credit-24_9b10786474.jpg)