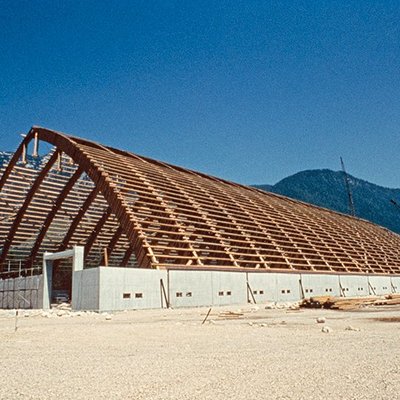

Salt Storage Hall

Ebensee Saltworks

Storage of the

white gold

The primary function of the hall is to store salt, a bulk material that is conveyed into the hall via a conveyor belt located at the ridge of the hall. The size and geometry of the hall are designed to meet these requirements. A three-hinged frame structure was constructed with a span of approximately 63 m, a height of about 28 m, and a length of 120 m. The frame members were arranged at 6 m intervals, with an arc radius of approximately 58 m, tailored to the cone shape of the salt storage. Components were manufactured in lengths of up to 22 m. Each half of the arc was glued together on-site using finger-jointed assembly.

The corrosion issue necessitated the exclusion of steel parts in joints, supports, and connections, as would typically be used.

Assembly only in fair weather conditions

The two halves of the truss are hoisted by 2 mobile cranes, while the assembly workers are brought up to construction height in a kind of gondola by another crane. This personnel transport had to be specially approved and classified. The slender beams, only 22 cm wide, had to be stabilized with cable tensioners. No wind was allowed to come up, so constant contact was maintained with the weather station. Successively, the secondary structure of the rafters was produced with distance connections to secondary trusses already installed to achieve extensive side supports.

The hall roof was covered with corrugated asbestos cement sheets, which also had to be custom-made to fit the curved shape. The hall was expanded for the first time 10 years later and still fulfills its function almost 50 years later.

- Client

- Österreichische Salinen AG

- General contractor

- PORR AG

- Overall construction period

- 1976/1977